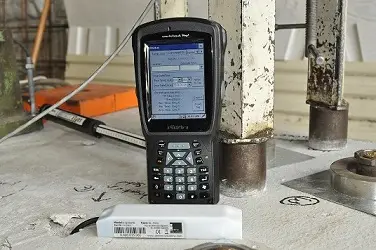

HardTrack Cloud Sensor

HardTrack empowers you to remotely monitor real-time concrete temperatures so that your concrete pour stays within the specified Thermal Control Plan (per 207.4R-05 ACI). No need to visit the job site several times per day or per week. Just activate the cloud sensor and return to your office. The temperature data is collected and uploaded to the cloud automatically.

View real-time graphical information on the web-based HardTrack Dashboard using your iPhone or Android device.

You will be amazed at how simple concrete temperature monitoring has become using HardTrack Cloud Sensors!

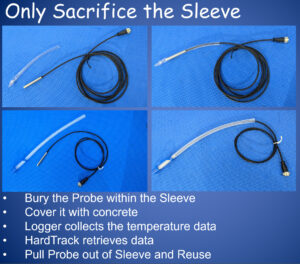

• Bury the probe.

• Bury the probe.

• Cover it with concrete.

• The cloud sensor collects the temperature data and uploads it to the cloud.

• View the data as frequently as you wish.

• Setup Alerts that will notify you if the pour is getting too hot or too cold or if any sensor has moved outside of your thermal control plan parameters.

• Cloud sensor comes with a replaceable battery that can last up to 3 years depending upon use.

HardTrack Cloud Sensor comes with (1) built-in ambient temperature sensor and (4) ports that allow you to deploy temperature sensor probes at distances of up to 100 meters (328.08 ft.) from the device.

HardTrack Cloud Sensor II comes with (1) built-in ambient temperature sensor and (4) to (25) ports which allow you to deploy temperature sensor probes at distances of up to 100 meters (328.08 ft.) from the device.

– enough rechargeable battery power to monitor your concrete pour for up to 60 days

– backup battery power, just in case your rechargeable battery power runs out

You will be able to monitor many pours using a single cloud sensor device.

Allows for the safe collection of temperature logs Remotely while you stay at home or at the office, which lowers your costs by saving time and money.

Armor Sheath is available for temperature sensor probes when your specifications require armored sheath on your concrete temperature sensor cables.

Want to take the next step to save time and money?

HardTrack will automate the process of determining Concrete Maturity according to ASTM C1074 without the need to visit the job site several times per day.

Fifty years ago, engineers discovered the many advantages Concrete Maturity has over the destructive process of measuring the strength of the concrete. However, because there were so many problems inherent in the capture of in-situ temperatures using sensors and wires, Concrete Maturity has been slow in being accepted.

Compared to the destructive method where you break the cylinders or beams, concrete maturity is:

• Easier

• Safer

• Faster

• More Reliable

• More Accurate

• Cost Effective