Components of Wireless Concrete Temperature Monitoring

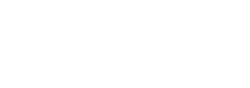

Wireless Temperature Sensor

One of the significant wireless concrete temperature monitoring components we use is a Wireless Logger. Collect concrete placement’s temperature and maturity information with no more broken wires. HardTrack includes a temperature logger with an accuracy that exceeds the ASTM C1074 requirements.

HardTrack wireless sensors get rid of all the wires found in competing solutions. A memory capacity of 10,000 temperature logs in its memory and a battery life of 5+ years make HardTrack wireless sensors an ideal solution. The logger can be programmed to wake up, read, and record the ambient temperature at user defined intervals. The stored information is read at any time you wish; there are no restrictions on the number of times it is read. Above ground, with a good line-of-site, wireless HardTrack sensors can be read a up to 300 feet using a Handheld or up to 1,000 feet using the HTC Gateway.

HardTrack Cloud Gateway (HTC Gateway)

– Monitor your concrete placements using reusable wireless concrete temperature sensor loggers

– Only sacrifice the temperature sensor cable probe attached to each remotely deployed wireless temperature logger– Wireless Sensors have a 5+ year battery life

– Reads wireless temperature sensors at distances up to 1,000 feet/300 meters in all directions

– For larger job sites, extend your range with a repeater, gaining you another 1,000 feet/300 meters– GPS Location Reporting of your HTC Gateway

– Onboard Ambient Temperature sensor can be added to all placements for monitoring

– Extensive library of configurable monitoring specifications so that final reports generated into Excel Spreadsheets meeting project owner requirements

– Online real-time concrete temperature monitoring dashboard

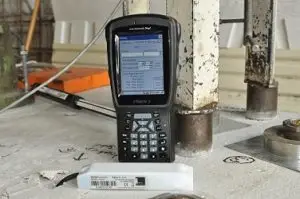

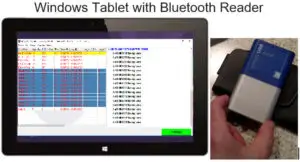

Handheld Portable or Windows Tablet and Bluetooth Reader

The system uses a portable handheld device or Tablet to read and write to the Wireless RFID tag buried in the concrete. You also have the option to run HardTrack on a PC using a Stationary Reader. This allows you to read your Temperature Logs from the Construction Office or remotely with either an Internet connection at the construction site or a cellular Modem. The HardTrack Desktop Wireless Solution includes cellular data plans setup for you by Wake, Inc

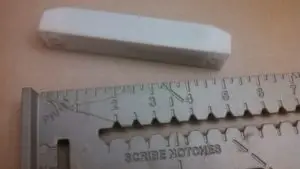

Wireless Reader

The Reader allows HardTrack to communicate with the Wireless RF Temperature Logging Tags. It allows HardTrack to “Talk” with the RFID Tags. It also acts as the transceiver and holds the antenna.

Should you have several RFID tags within the same general reading area, the Reader is smart enough to speak with only one tag at a time, and it will let your know which tag you are addressing and whether you are reading or writing to the tag.

Concrete Maturity Software

The Concrete Maturity (ASTM C1074) Software is designed to work specifically with the above-mentioned components. It allows for inputting all of the necessary information, including the sample mix design data to create the concrete maturity curve. Once you have collected the information from the tag, you can immediately display the concrete strength. The software also displays a graph of the time and temperature for a quick visual check. It gives the user a number of options such as using either the Nurse-Saul equation or the Arrhenius methodology. It will also give you the choice of using the standard 28-day or an expatiated maturity calculation.

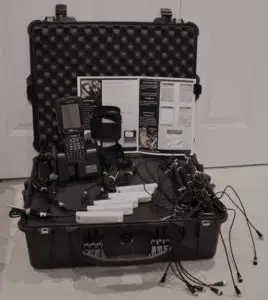

The Starter Kit

The Starter Kit includes a handheld portable computer or Tablet and Bluetooth Reader, the Reader, an antenna, the Concrete Maturity Software loaded on the handheld and the RFID Wireless Concrete Temperature Logging Tags. You have the choice of tags with or without the external probe or a combination. You will also receive an outstanding User Manual, that will take you step by step through all of the processes to get you up and running. An on-site visit is available, but to date, we have never had anyone find it necessary for us to make a visit. It truly is as easy as 1-2-3. We also offer support for you at no cost.

Why pay $85+ for wireless sensors? If you use 200 sensors per year, you will save $45,000 over 5 years with HardTrack vs. the Competition

HardTrack Wireless Solutions